Tote Systems: Leading The Way In Fda And Cgmp-compliantTote Systems: Leading The Way In Fda And Cgmp-compliant

In industries like food and drinkable, pharmaceuticals, chemicals, and nutraceuticals, the demand for competent, safe, and lamblike material treatment solutions is constantly development. TOTE Systems has risen to meet this take exception, establishing itself as a leadership U.S. manufacturer of STAINLESS-steel equipment premeditated specifically for dry and pulverise stuff handling. With over 40 eld of expertness, Industrial Totes has become a sure name in creating structured treatment solutions that ascertain operational efficiency, product tone, and regulatory compliance.

Why TOTE Systems Stands Out

TOTE Systems focuses on providing advanced equipment plain to industries where cleanliness, precision, and safety are predominant. Their products are studied not only to meet but pass rigorous standards, including cGMP, FDA, USDA 3A, and other restrictive requirements. Whether it s for commixture, transporting, or discharging powders, TOTE Systems offers serviceable and TRUE solutions that keep processes smoothen and efficient.

Key Products of TOTE Systems

TOTE Systems’ production range is various and innovational, allowing businesses in thermostated environments to attain more while minimizing risks. Below are the key offerings from the denounce:

1. Integrated Blending Systems

One of TOTE Systems’ standout products is its closed-loop blending SYSTEMS. These SYSTEMS allow for powder mix straight inside the TOTE container, which offers several benefits. By using this SYSTEM, companies tighten cross-contamination risks, lour downtime, and make cleansing processes easier. Since blending occurs in the same , there is no need for additive treatment or transferring between equipment, which can sometimes lead to spills or taint.

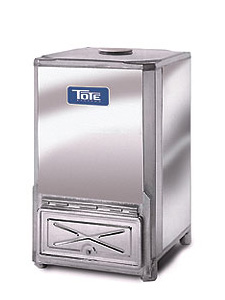

2. Tote Containers

The keep company s TOTE containers are studied with both work and refuge in mind. Made from STAINLESS steel, these containers are serviceable and tolerable to contamination, qualification them nonpareil for medium applications. The plan of these TOTEs is efficient to make them easy to handle, whether they re being occupied, stored, or emptied. Their versatility is hone for industries that need unrefined solutions for both small and boastfully-scale operations.

3. Dumpers and Lifts

TOTE Systems also offers high-quality dumpers and lifts, vital for industries where manual treatment is minimized to reduce worker tire and the risk of contamination. These SYSTEMS allow for easy of ingredients or materials into big processes or containers. The lifts see that materials are transported to the height or put together, all while maintaining the integrity of the materials being handled.

4. Tilt Discharge Units

When it comes to emptying debatable powders or materials that don t well flow, tilt units from TOTE Systems are a game-changer. These units use solemnity-fed techniques to verify the flow of materials, ensuring that powders are discharged cleanly and with efficiency. For industries dealing with wet, clumpy, or highly cohesive powders, this equipment is invaluable. The design minimizes waste, ensures precise saving, and helps reduce cleanup and downtime, making production processes much more operational.

Meeting Industry Standards

TOTE Systems is particularly known for its power to plan and manufacture that meets the highest restrictive standards. In industries where submission is critical, TOTE Systems provides that fulfills FDA, USDA, and cGMP regulations. This is especially meaningful for sectors like food and beverage and pharmaceuticals, where the quality and safety of products are non-negotiable.

The keep company’s focus on cleanroom and hygienic designs ensures that their products can be used in environments where contamination risks need to be decreased. Whether in a cleanroom or a product shock, TOTE Systems is well-stacked to wield the most rigorous requirements, ensuring that processes continue amenable and product timber is consistently retained.

Efficiency Gains with TOTE Systems’ Solutions

One of the most substantial benefits of using TOTE Systems’ is the efficiency it brings to dry and powderize material treatment. Their SYSTEMS streamline product processes by reduction the need for manual of arms intervention and minimizing downtime. This leads to faster product multiplication, lower push , and magnified overall productiveness.

With the original unsympathetic-loop blending SYSTEMS, for example, there is no need to move materials between various pieces of for commixture. This reduces the potential for contamination, speeds up the entire work on, and eliminates supernumerary treatment. TOTE Systems’ tilt units also put up to efficiency by making sure powders flow decently, without cachexy material or requiring inordinate cleanup.

In summation, the equipment’s robust and serviceable plan means that businesses can rely on these SYSTEMS for years, reducing sustentation costs and flaring the return on investment.

Durability and American Engineering

TOTE Systems takes congratulate in its American engineering and manufacturing processes. With a focalise on lastingness and long-term public presentation, the company produces equipment that stands the test of time. Stainless nerve construction ensures that TOTE Systems’ equipment can withstand the wear and tear of regular use, while also providing resistance to the chemicals and harsh conditions often ground in industrial settings.

This strength is particularly key for businesses that rely on equipment in operation around the clock. The dependability of TOTE Systems machines substance less breakdowns, less downtime, and at last, a more homogeneous and productive surgery.

The TOTE Systems Advantage in Dry and Powder Material Handling

TOTE Systems long-standing commitment to quality, efficiency, and submission has positioned it as a drawing card in the domain of dry and pulverise stuff handling. By offer organic, innovative solutions like their unsympathetic-loop shading SYSTEMS, tilt units, and STAINLESS-steel TOTEs, TOTE Systems has become a trusty spouse for businesses in highly thermostated industries.

For companies that need to streamline their processes, tighten downtime, and exert product quality while ensuring submission, TOTE Systems provides the equipment and expertise to meet those needs. With a sharpen on enduringness, efficiency, and regulative adherence, TOTE Systems continues to play a crucial role in transforming the stuff treatment manufacture for the better.

The next time you look for dependable, efficient, and nonresistant handling solutions for your dry or powderise materials, look no further than TOTE Systems. Their American-engineered is stacked to help you optimize your processes and bring home the bacon in a fast-paced, restrictive-driven environment.