PCBs which can be created for SMT construction use smaller components than before, which in turn causes the whole PCB to be more compact and slimmer with higher energy efficiency. These benefits permit present-day PCBs to be found in a larger variety of devices including, handheld and notebook pcs, intelligent telephones, or devices that want a set, compact PCB control table as opposed to one with large dimensions. For these causes, SMT-manufactured PCBs have gained wide acceptance across a from digital world style technicians to OEM machinery makers, among others.

Many people do not like to cope with surface install engineering (SMT) due to some misinformation about it. There exist several excellent referrals for commercial construction, but not much is discussed prototyping and hand soldering with SMT. SMT is a form of electric element package. Surface Install (SM) is 1 of 2 kinds of electric components; the second reason is through hole (TH). SM components are designed for loading and soldering on a specific part of the produced circuit board. TH is designed for running and printing using one side of the world board.

SMT offers many crucial benefits over though TH — including smaller bodily size with the exact same electrical purpose — are cheaper when it comes to organic product, have less unwelcome consequences and are faster for computerized models to place. The greatest advantage of SMT is the true property stored by not positioning holes through the board. Which allows the table to possess more track and therefore be scaled-down in size.

SMT increasingly influences these associated with development, restoration, and change of electronics. SMT equivalents are quickly exchanging the TH parts as companies raise their investment in SMT manufacturing equipment to reap the benefits. Many of these urban myths range from the proven fact that SMT involves special instruction, skilled PCBs, specific costly gear, and other parts which can be hard to find. Most produced circuit panel construction properties do not have any issues with SMT. Learn before you set an order. To utilize SMT without stress, you should exercise your approach, keep a constant hand, have great perspective or use some sort of zoom, and make use of a excellent couple of tweezers.

SMT resistors are easy to similar together and quick to solder and de-solder. Not working on both sides of the board at the same time frame decreases frustration. When working with RF signals, unwanted results in SMT pieces are fewer than parts. When room is limited, SMT pieces fit perfectly on the holes of VERO board and posses the ability to mix with designs that use leaded parts. When opening drilling is a problem, SMT streamlines that as you load and solder on the same side.

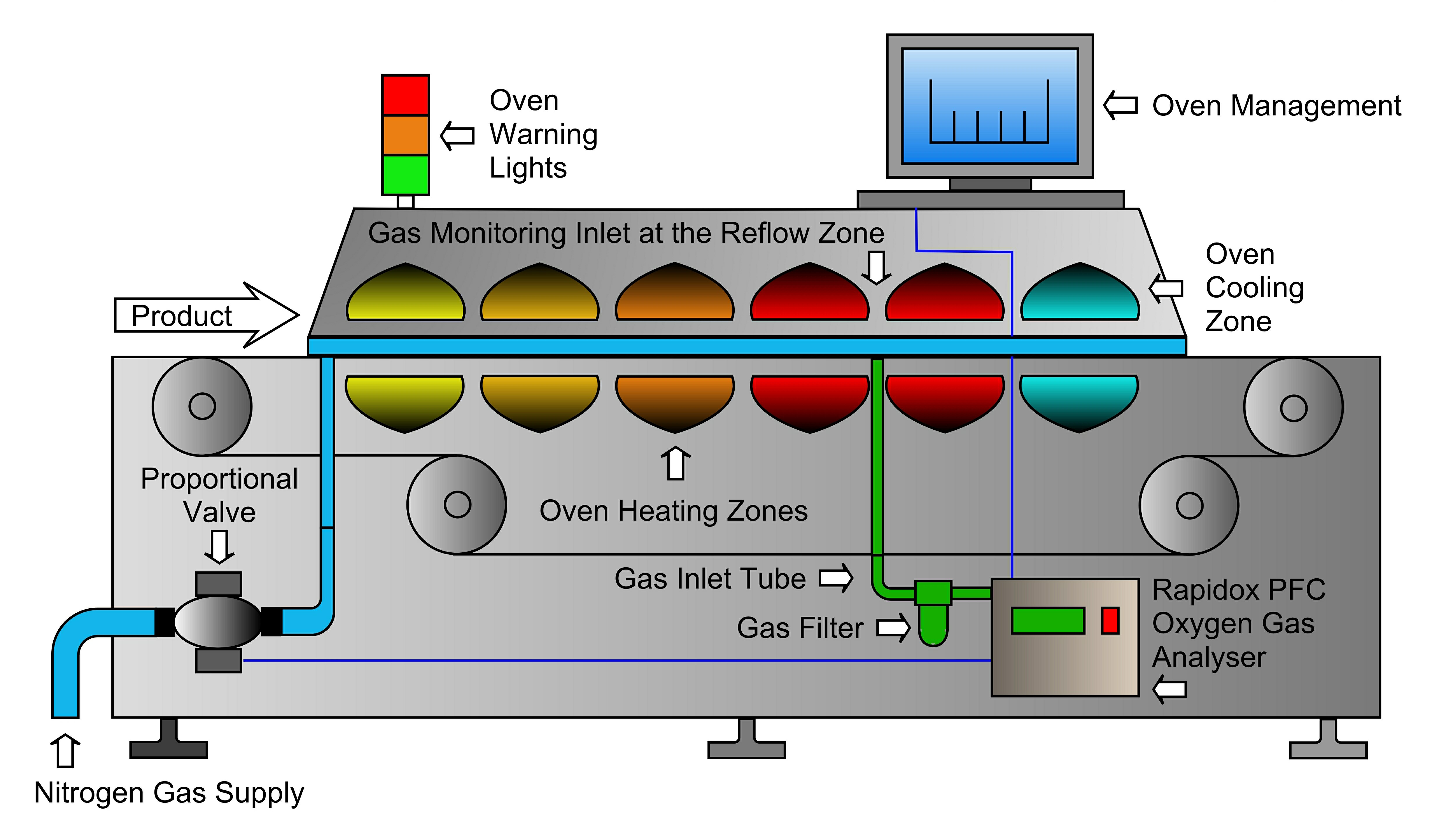

Excellent soldering methods have practice. Additionally there are several tips to follow, including keeping the enterprise table clear, utilising the right soldering iron for the work, selecting the correct hint and applying solder flux where possible. For training, use SMT resistors because they are maybe not easily damaged. It’s possible to obtain several SMT Reflow Oven components from surplus or trash equipment. It preserves income and enables or excellent de-soldering practice. Porcelain capacitors are difficult while they crack easily. Resistors, inductors and transistors can be verified for proper operation, but extortionate temperature may possibly injury the device. For a list of all pieces, there a few excellent aspect suppliers. DigiKey is among the popular ones. You can even scavenge old computers, cell phones, TV’s, etc.

Manager of Marketing and Revenue for Sierra Tracks, Inc. Amit is tasked with exploring and establishing new areas for High Density Interconnect PCBs and Microelectronic substrates. Sierra Tracks, Inc. has primarily served the fast turn prototype market and is now definitely developing the Medical, Military and Automotive markets. Prior to joining Sierra Circuits, Inc., Amit Bahl was a part of IBM’s Worldwide Solutions group, wherever he worked on automating and optimizing organization processes using the latest Information technologies. Amit Bahl obtained his B.S.C in pc research with a small in marketing from UCLA.